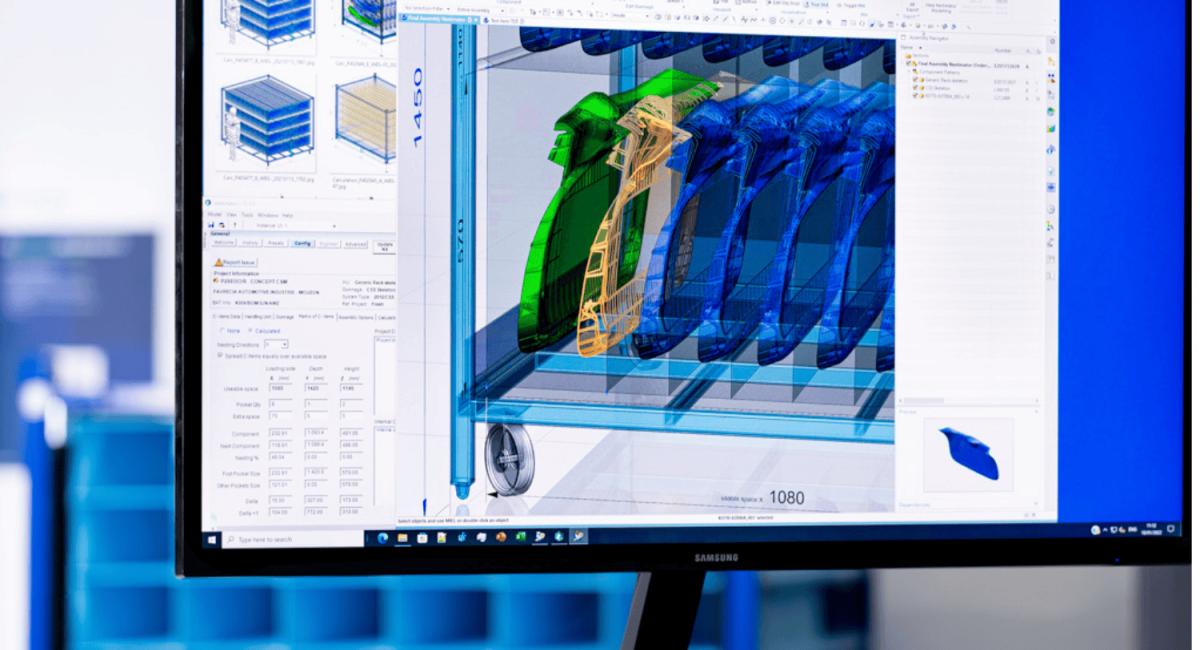

KTPconTeyor development

Well-conceived from start to finish

We implement our high quality and safety standards consistently - from the initial idea to the finished packaging solution. While our development, production and final inspection of our KTP containers are centralized at our headquarters in Germany to ensure complete control and precision, we are proud to operate internationally with production sites in Poland, Moldova, Türkiye, Germany and Mexico. This global footprint enables us to combine engineering excellence with local responsiveness, ensuring reliable quality and service wherever our customers are.